XRAY detection equipmentHaving a setXRAYThe imaging system is achieved throughNon destructive testing of industrial products using X-raysA device. It is generated by high-speed electron bombardment of the anode targetXRadiation, transmission of the inspected components, andThe internal structure image of the component obtained from the imaging device can quickly and accurately determine the internal structure of the inspected componentNo defects.

The non-destructive testing industry has long beenXRAY imaging method, as an important means of detection, has been widely used in production; Our company has developed a 2.5D XRAY detection equipment that meets market demand. It has significant characteristics such as high detection efficiency, low detection cost, high sensitivity, and high detection accuracy. Fully functional, adopting universality, serialization, and standardizationThe standardized research and development concept ensures that the system is easy to operate, safe and reliable, structurally sound, and aesthetically pleasing

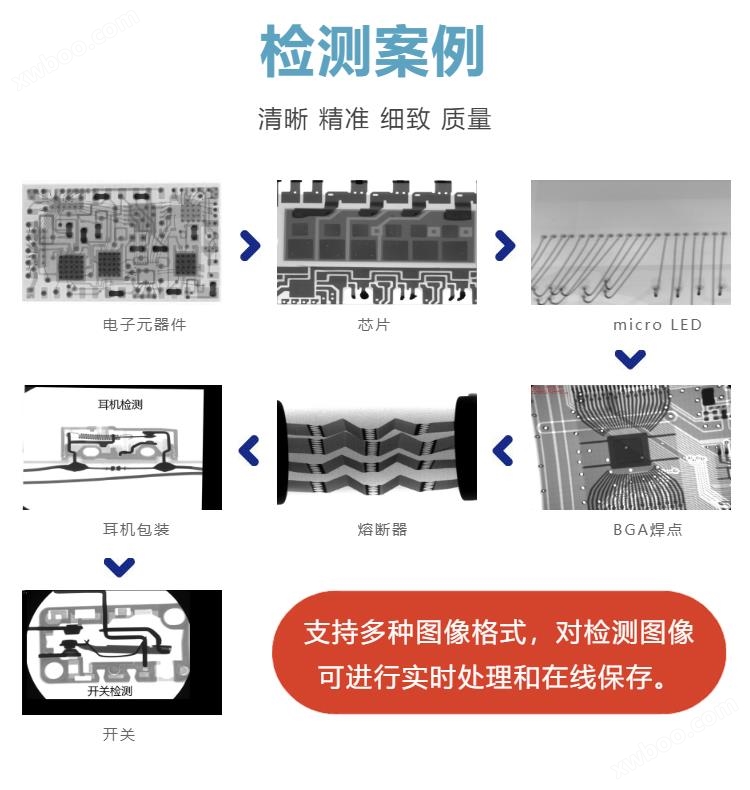

Zhengye TechnologyXRAY detection equipment is constantly iterating and updating, starting with manual development from the very beginningCustomized fully automatic detection equipment available now; From the planeThe development of 2D detection to stereo 2.5D and 3D has gone through more than 10 years; The current 2.5DXRAY detection system integrates various high-precision and cutting-edge technologies such as motion control, image acquisition, and algorithm analysis; It has the characteristics of high image resolution, large magnification, compact structure, light weight, and easy maintenance. At present, the equipment is widely used in fields such as semiconductors, new energy, capacitors, electronics, automotive parts, and food.

|

model parameter |

XG5010A(2.5D) CD ONLY |

XG5010A(2.5D) Standard Edition |

XG5010A(2.5D) High end version |

|

equipment performance |

|||

|

External dimensions |

2200mm(L)x1400mm(W)x2000mm(H) |

||

|

Weight |

1800 Kg |

1800 Kg |

2000 Kg |

|

power supply |

110V/220V/16A |

110V/220V/16A |

110V/220V/20A |

|

power |

4 Kw |

4 Kw |

4.6 Kw |

|

Tilt angle |

±60° |

||

|

Rotating stage |

0° |

0° |

360° |

|

number of axles |

5 axes |

5 axes |

6 axes |

|

Product input(Optional)) |

Manual scanning of codes |

Manual/automatic scanning of codes |

Manual/automatic scanning of codes |

|

detection range |

Manual five sided perspective inspection |

Manual five sided perspective inspection |

Automatic five sided perspective detection |

|

detection |

Manual/algorithmic detection |

||

|

stage |

410mmx460mm |

410mmx460mm |

410mmx460mm |

|

Maximum load-bearing capacity of the loading platform |

6Kg |

6Kg |

5Kg |

|

Radiation amount |

<1uSV/h |

||

|

X-ray source performance |

|||

|

Light tube model |

PXS series |

G series |

|

|

Light tube type |

Reflective closed tube |

Transmission type closed tube |

|

|

Maximum tube voltage |

110Kv |

100Kv |

|

|

Maximum tube current |

250uA |

200uA |

|

|

emission angle |

120° |

168° |

|

|

minimum resolution |

7um |

4um |

|

|

Flat panel detector performance |

|||

|

Detector model |

Whale series |

NDT series |

MFG series |

|

Detector Type |

Amorphous Silicon |

New TFT |

Amorphous Silicon |

|

resolution |

4.0 Lp/mm |

5.8 Lp/mm |

10Lp/mm |

|

pixel size |

125um |

85um |

49.5um |

|

pixel matrix |

1024mmx1248mm |

1536mmx1536mm |

2312mmx2904mm |

|

Effective imaging area |

160mmx128mm |

130mmx130mm |

114mmx143mm |

|

A/D conversion bits |

16bit |

16bit |

14bit |

|

Frame rate (1x1) |

30 |

20 |

10 |

|

Characteristics and Applications |

applyPCBAVoid rate andSoldering effect testing, new energySource and capacitor industry fusesWaiting for on-off and linear testingTesting, this model is mainly designed for Testing the internal structure and process effect of the product |

Mainly used for internal structure and dimensional inspection of products, with an accuracy of 0.01mm, widely used in PCBA and new energy fields High precision measurement equipment for domain |

Multi sided automatic perspective inspectionTesting is mainly used in complex product structures with high precision requirements, suitable for research and development laboratories, and sampling inspections Check, high-precision inspection process, etc |